Operating Plant

Operation & Maintenance

VASAVI provides power plant operations and maintenance (O&M) solutions for the power plants around the world. We have our core competency to operate and maintain power stations in optimizing the plant performance. Our O&M portfolio delivers world-class performance, in plant loading factor, availability & reliability. We offer tailored solutions, geared for optimal performance over the lifetime of the plant. Our activities include:

- Establishing the O&M organization structure

- Staff training and development

- Developing and installing management systems and procedures

- Day-to-day operations and maintenance

- Plant performance monitoring, diagnostics and efficiency enhancement

- Management and evaluation of maintenance contracts, including the LTSA

- Technology evaluation and spares management

- Health, safety and environmental management

- Planned and unplanned maintenance (including overhauls)

Field Maintenance Services

VPSPL is an experienced field services specialist organization for plant owners, OEMs and engineering consultants, offering full-scope of mechanical, electrical & instrumentation services. VPSPL manages professional workmanship with adherence to plant safety standards & OEM procedures. VPSPL’s clientele for maintenance service work scopes includes the power generation facilities, oil & gas, cement, sugar, steel production plants, and the petrochemicals industries.

VPSPL has gained the trust of plant owners and operators for over three decades for turnkey field services. Our project managers, technical advisors, engineers and craftsmen are seasoned professionals with a broad range of experiences whose skill sets cover both common and unique models of turbo machinery from different OEMS around the world. Our reputation for providing outage support during emergency breakdown, highly skilled pool of in-house workforce, spares supply capability and high standard repairs facility has enabled us to become one of the most recognized and trusted names in the power generation industry.

Field Maintenance Services Capabilities

VPSPL brings more than three decades of experience in providing specialty maintenance services to the steam turbine owners. As an independent service provider, VPSPL leverages this experience from all segments of the power generation industry to provide cost-effective solutions to utilities, original equipment manufacturers (OEMs), third party providers and independent power producers (IPPs).

Working in close partnership with the turbine manufacturers and asset owners, we can execute the maintenance projects from planning to execution, safely and efficiently to exacting standards. Working round the clock, our on-site teams work together to complete the project to the highest quality. With commissioning and trial run completing the maintenance process, the steam turbine is then ready to resume its life cycle generating energy reliably.

Steam Turbine Maintenance Capabilities

- Minor & Major Inspection

- Bearing Inspection

- Condition Monitoring & Vibration Analysis

- Shaft Balancing

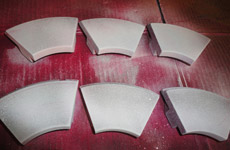

- New / Refurbished Capital and Consumable Parts

- Steam path Repairs

- Non Destructive Testing

- Technical Advisor - Mechanical, E&I, Commissioning

- Steam Turbine Technician

Steam Turbine Fleet Capabilities

- KWU - German Design: 500 MW, 250 MW, 210 MW, 120 MW

- General Electric - USA: 180 MW, 140 MW, 62.5 MW, 9.25 MW

- LMW-Russian Design: 210 MW

- Ansaldo-Italian Design: 200 MW

- Poland Design: 120MW

- Skoda - Czech: 110MW

- MHI-Japan: 70 MW

- Siemens-Germany: 67.5 MW

- Hitachi-Japan: 30 MW

- BHEL: Up to 500 MW

- Franco Tosi: Up to 210 MW

- Toshiba: Up to 500 MW

- Shanghai Electric Company: Up to 660 MW

- Harbin: Up to 660 MW

Gas turbines are designed to last at least 25 years but periodic inspection and maintenance are paramount to their life cycle cost efficiencies. VPSPL provides a complete field services package for the high performance of gas turbine, based on the OEM guidelines to increase its lifetime and ensure the maximum return on investment of your asset. Our field services team of highly skilled & experienced technical advisors, fact finders, commissioning engineers & craftsmen, equipped with the tools and personal protective equipment carry out planned outages to complete essential maintenance works including repair and replacement of all major components. In addition we have rapid response teams to handle the unscheduled breakdowns, troubleshooting and repairing faults to minimize turbine downtime.

Gas Turbine Maintenance Capabilities

- Combustion Inspection, Hot Gas Path Inspection, Major Inspection

- Type A, Type B and Type C Inspection

- Condition Monitoring & Vibration Analysis

- Shaft Balancing

- New / Refurbished Capital and Consumable Parts

- DLN / DLE Fuel nozzle tuning

- Hot Gas Path and Compressor Repairs

- Non Destructive Testing

- Technical Advisor - Mechanical, E&I, Commissioning

- Gas Turbine Technician

Gas Turbine Fleet Capabilities

- General Electric / BHEL : Frame 3, 5, 6B, 6FA, 7EA, 7FA, 9E, 9FA

- ABB / Alstom: GT8C, GT11, GT13

- Ansaldo Energia / Siemens: V64.3, V94.2, V94.3A

- Fiat / Westinghouse / MHI : TG16, TG20, TG50C, TG 50D5, W191, W251B2, W251B8, W251B11, MW701D, MW701F

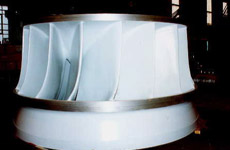

Our field services team covers the complete spectrum of hydro turbine & its generators. Highly skilled & experienced team of engineers & craftsmen can plan & execute the maintenance of hydro turbine. We also assist the plant owners in sourcing the parts and emergency support services. Proper strategic planning is essential to execute the outage with minimum downtime and keep the machine running safely and reliably. Long term service agreements, including technical support and parts agreements, help manage risk during normal plant operations. We offer sourcing of critical parts, control upgrades, and field services.

Hydro Turbine Maintenance Capabilities

- Capital Maintenance

- Plant Auxiliaries

- Condition Monitoring & Vibration Analysis

- Shaft Balancing

- New / Refurbished Capital and Consumable Parts

- Non Destructive Testing

- Technical Advisor - Mechanical, E&I, Commissioning

- Hydro Turbine Technician

Hydro Turbine Fleet capabilities

- Francis, Kaplan Hydro turbines and generators of BHEL, Hitachi make.

For more than three decades, VPSPL has performed turnkey inspections of rotating machineries like compressor & pumps of several OEM manufacturers. VPSPL offers the technical advisory services, maintenance execution, project management, supervision, craftsmen, tooling, repairs, parts sourcing, and start-up support for these outages, bringing you a total turn-key package. We service the entire rotating machineries including its controls, auxiliaries and gearboxes. Our global presence, containerized tooling, and our on-site repair capabilities enable us to deliver rapid service turnaround service of your entire fleet.

Compressors & Pumps capabilities

- Minor Overhaul

- Boroscope

- Plant Auxiliaries

- Condition Monitoring & Vibration Analysis

- Shaft Balancing

- New / Refurbished Capital and Consumable Parts

- Non Destructive Testing

- Technical Advisor - Mechanical, E&I, Commissioning

- Compressor Technician

For more than three decades, VPSPL has performed turnkey inspections of rotating machineries like compressor & pumps of several OEM manufacturers. VPSPL offers the technical advisory services, maintenance execution, project management, supervision, craftsmen, tooling, repairs, parts sourcing, and start-up support for these outages, bringing you a total turn-key package. We service the entire rotating machineries including its controls, auxiliaries and gearboxes. Our global presence, containerized tooling, and our on-site repair capabilities enable us to deliver rapid service turnaround service of your entire fleet.

VPSPL has more than three decades of experience in performing generator maintenance and testing services. As the part of integrated services along with the turbo machinery maintenances, VPSPL also offers the maintenance of generator, providing customers options to support their availability and reliability of assets. Generally, maintenance of the generator is performed during the turbine outage. This approach reduces the overall downtime, as well as improves reliability. We have the right resources and the right people to provide the total turnkey maintenance of generator. We execute the generator overhauling & testing professionally and efficiently by managing all our resources.

Generator Maintenance Capabilities

- Generator Overhaul

- Electrical diagnostic testing

- Residual Life Assessment

- Generator Excitation System

- Boroscope

- Generator Auxiliaries

- Condition Monitoring & Vibration Analysis

- Non Destructive Testing

- Technical Advisor - Mechanical, E&I, Commissioning

- Generator Technician

Specialized Services

All the electrical equipments undergo the process of aging due to the continuous operating voltage stress, ambient temperature & moisture, transients, surges, spikes, etc. Electrical testing is an effective tool for evaluating the condition of the insulation & conductor of electrical machinery and appraises its fitness for the further usage. Our capabilities include the complete range of testing from insulation resistance test to tan delta and El CID test. We offer testing of:

Electrical Diagnostic Testing Capabilities

- Generator

- HV Motor

- Power Transformer

- CT & PT

- Relays & Circuit Breaker

Electrical Diagnostic Testing Offered

- EL-CID

- Partial Discharge Analysis

- Wedge Tightness

- DC Winding Resistance

- Insulation Resistance / Polarization Index

- Visual Inspection

- Power Factor Tests

- End Winding Resonance Test

- AC / DC High Potential

- DC Step Voltage

- Primary Injection test

- Secondary Injection Test

VASAVI offers complete field calibration services for the process instruments like pressure, temperature & flow. Calibration ensures that instrument measurement is accurate and within the limits required to maintain the safe plant operation. In the complex processes like power plant, periodic calibration to is very important to comply with both quality and safety standards. We can help you stay in compliance while reducing your costs and increasing process up-time. Our services include:

Controls & Instrumentation Calibration Capabilities

- Calibration of analog & digital instruments

- Calibration of transmitters

- Inspection of terminals

- Inspection of earthing points

- Calibration certificate & report

- Control System retrofit

- Generator Excitation Panel

Welded Joints, machined parts, industrial structures & pipelines experience extreme load and fatigue during their lifetime. Non-destructive evaluation (NDE), or Non-destructive testing (NDT), is a highly valuable technique that is used to validate the integrity of materials, detect instabilities, recognize failed components, or highlight an inadequate system. Our NDE / NDT capabilities include:

Non Destructive Testing Capabilities

- Liquid / Dye Penetrant Testing (DPT)

- Magnetic Particle Testing (MPT)

- Radiography Testing (RT)

- Ultrasonic Testing (UT)

- Eddy Current Testing

- Boroscopic Inspection

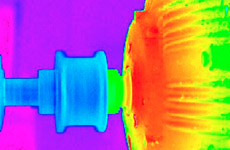

Rotating machineries with flexible rotors like turbine, compressors etc have an inherent issue of vibration. VASAVI has highly skilled professionals & gadgets to analyze the vibration. We offer cost effective solution of on-site shaft balancing. Expensive & time consuming transportation of the shaft to repairs workshop is not required, anymore. VASAVI offers transportable balancing facility.

Condition monitoring Capabilities

- Vibration Analysis

- Motor current signature analysis

- Oil Analysis

- IR / Thermograph

- Dynamic Balancing

Shortage of the skilled resources worldwide is a big challenge in front of the power industry. Plant professionals should get familiarized and master the modern technologies, advanced plant controls, sophisticated plant operating procedures, emergency responses etc to improve the safety, efficiency and the economy of power plant. Our specialists share their knowledge & experience to build a team of highly skilled resources and operate or maintain your plant safely. We offer the following course at our location and on-site:

Trainings Offered

- Safety Training - OHSAS / NEBOSH / NFPA

- Power Plant Familiarization Training

- Steam Turbine Operator Training

- Gas Turbine Operator Training

- Compressor Operator Training

- Plant Turnaround Management Training

- Mechanical Maintenance Training

- Electrical Maintenance Training

- Instrumentation Maintenance Training

- Condition Monitoring

- Vibration Analysis

- Industrial Hydraulics

- Industrial Pneumatics

- Control Valves

- Industrial Automation

- Painting & Sandblasting

- Non Destructive Testing